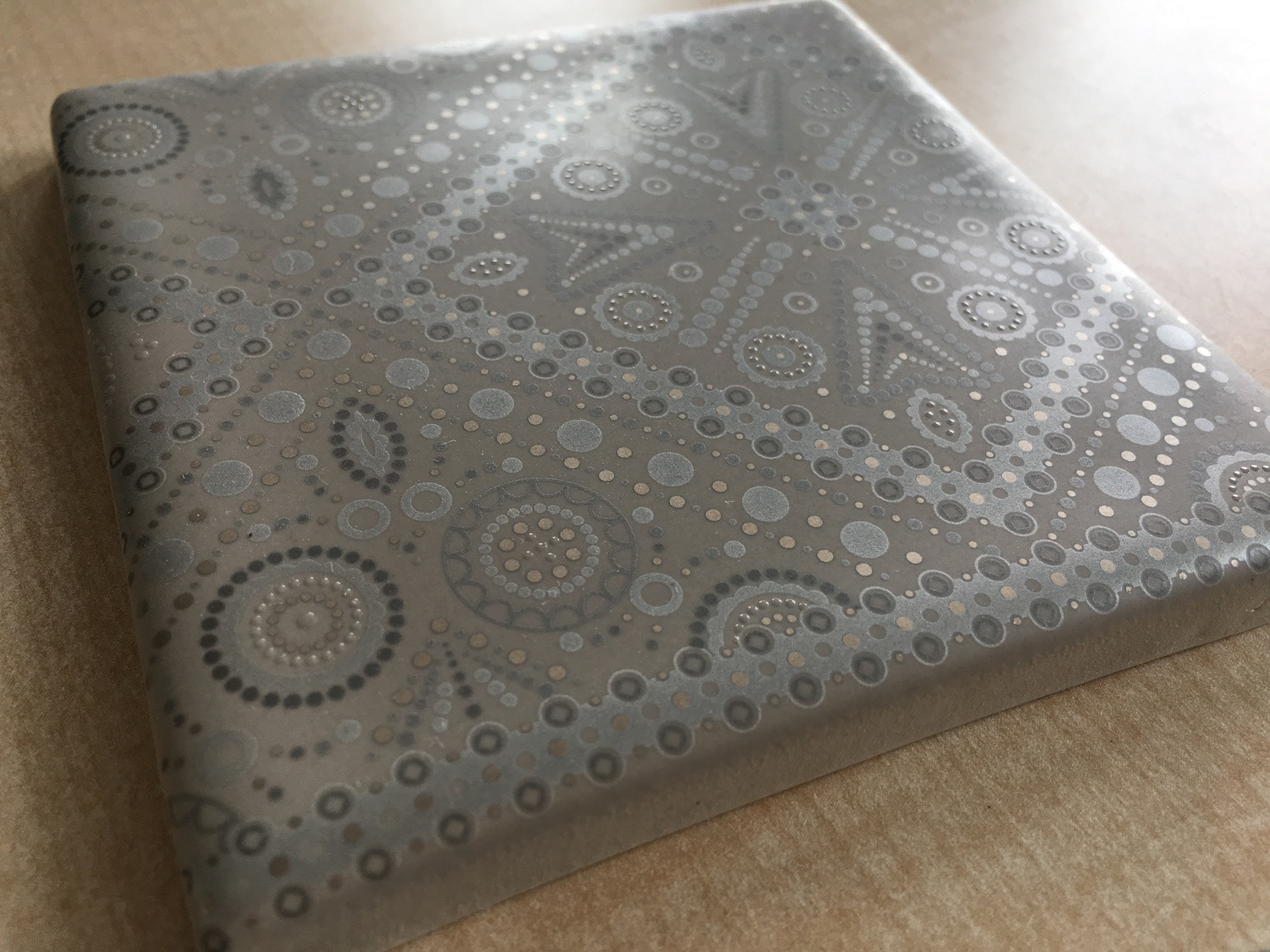

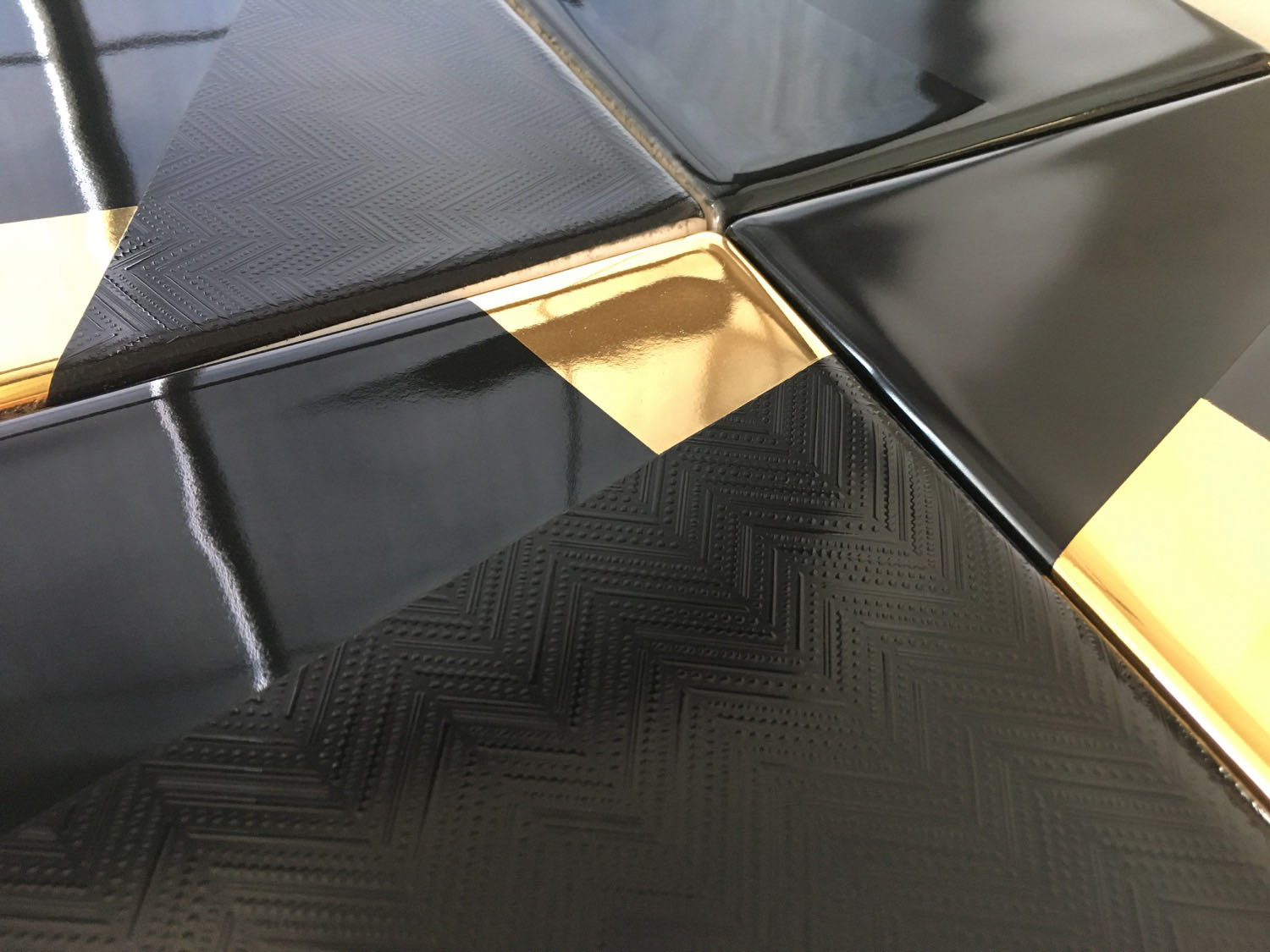

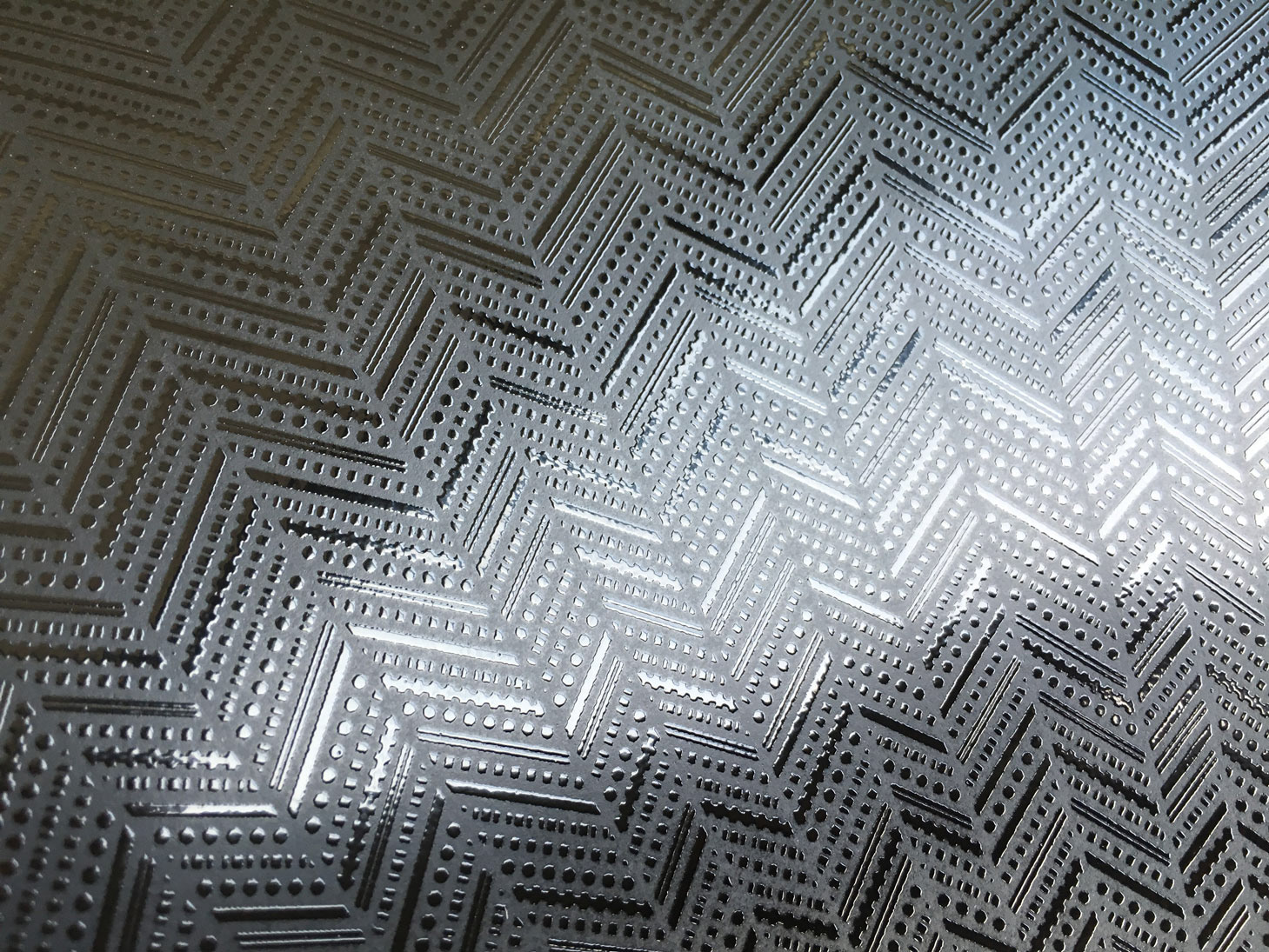

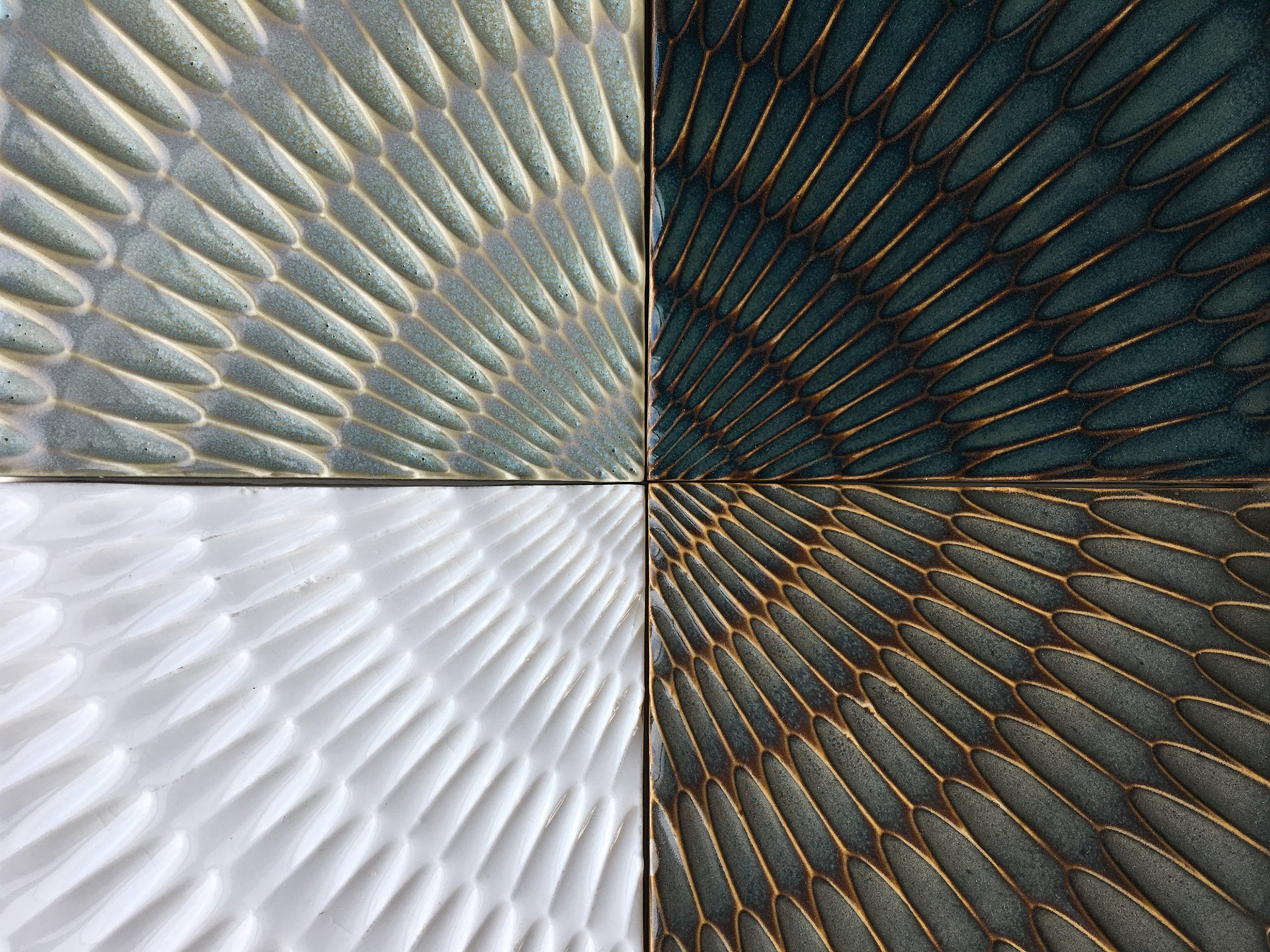

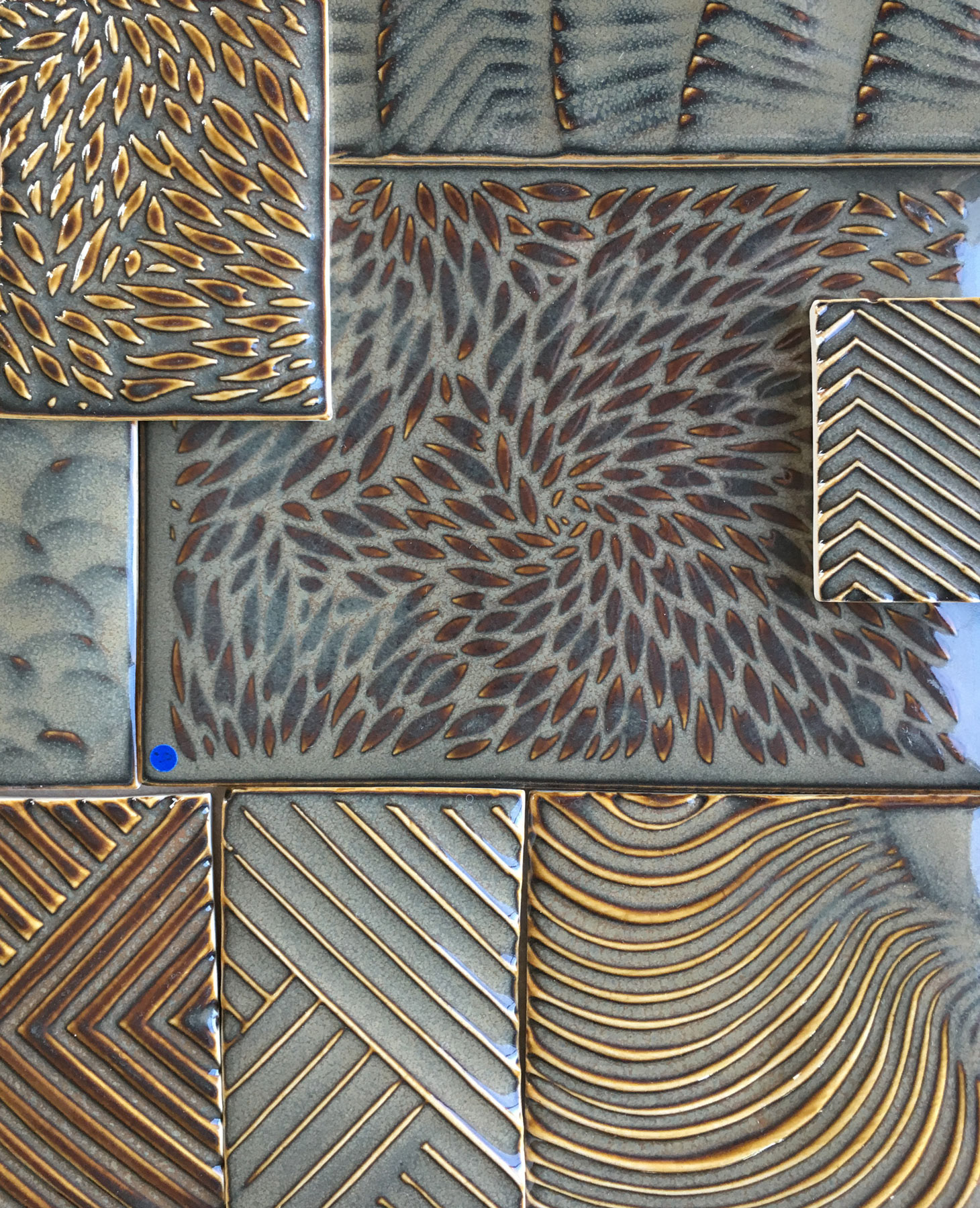

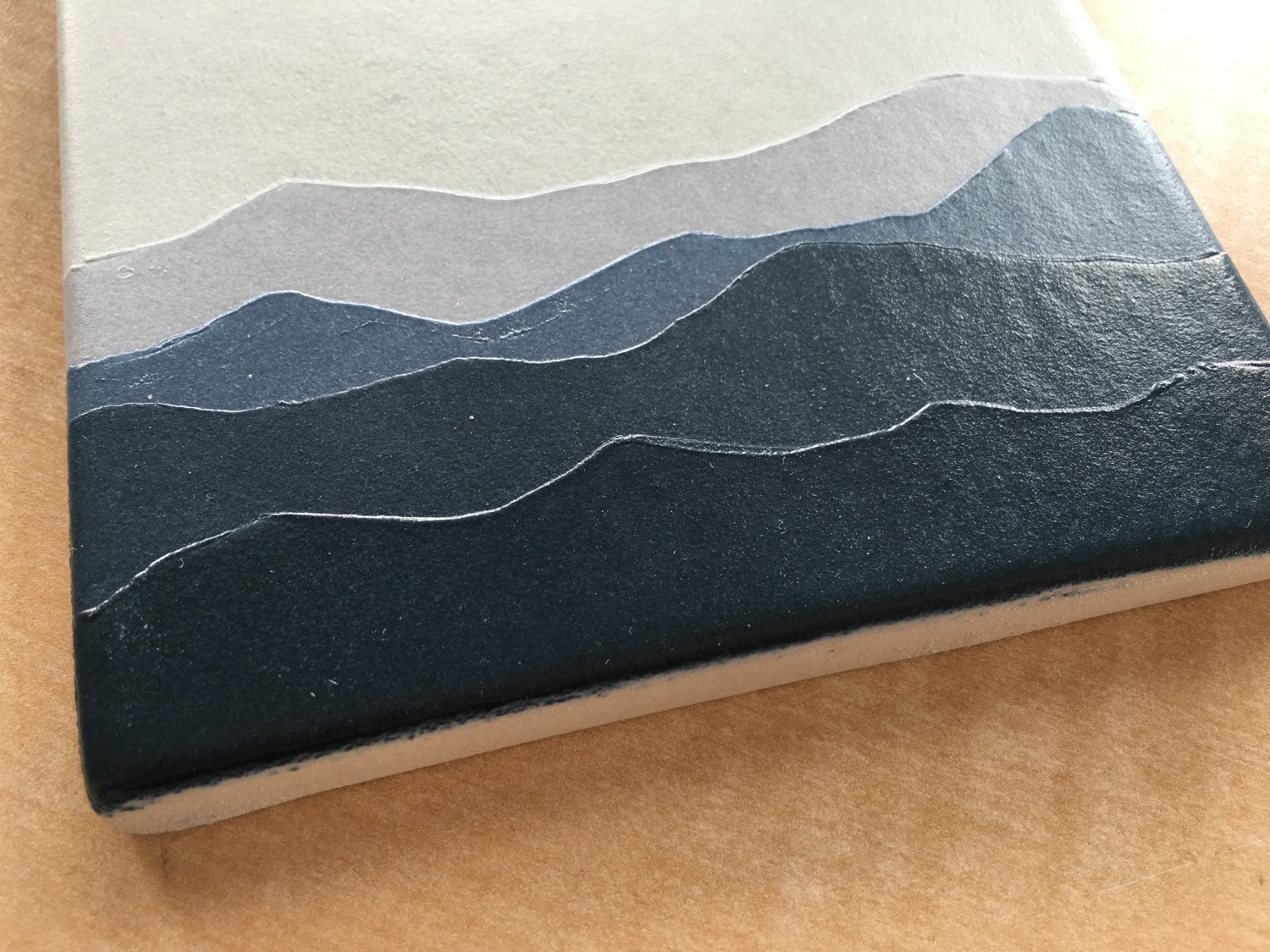

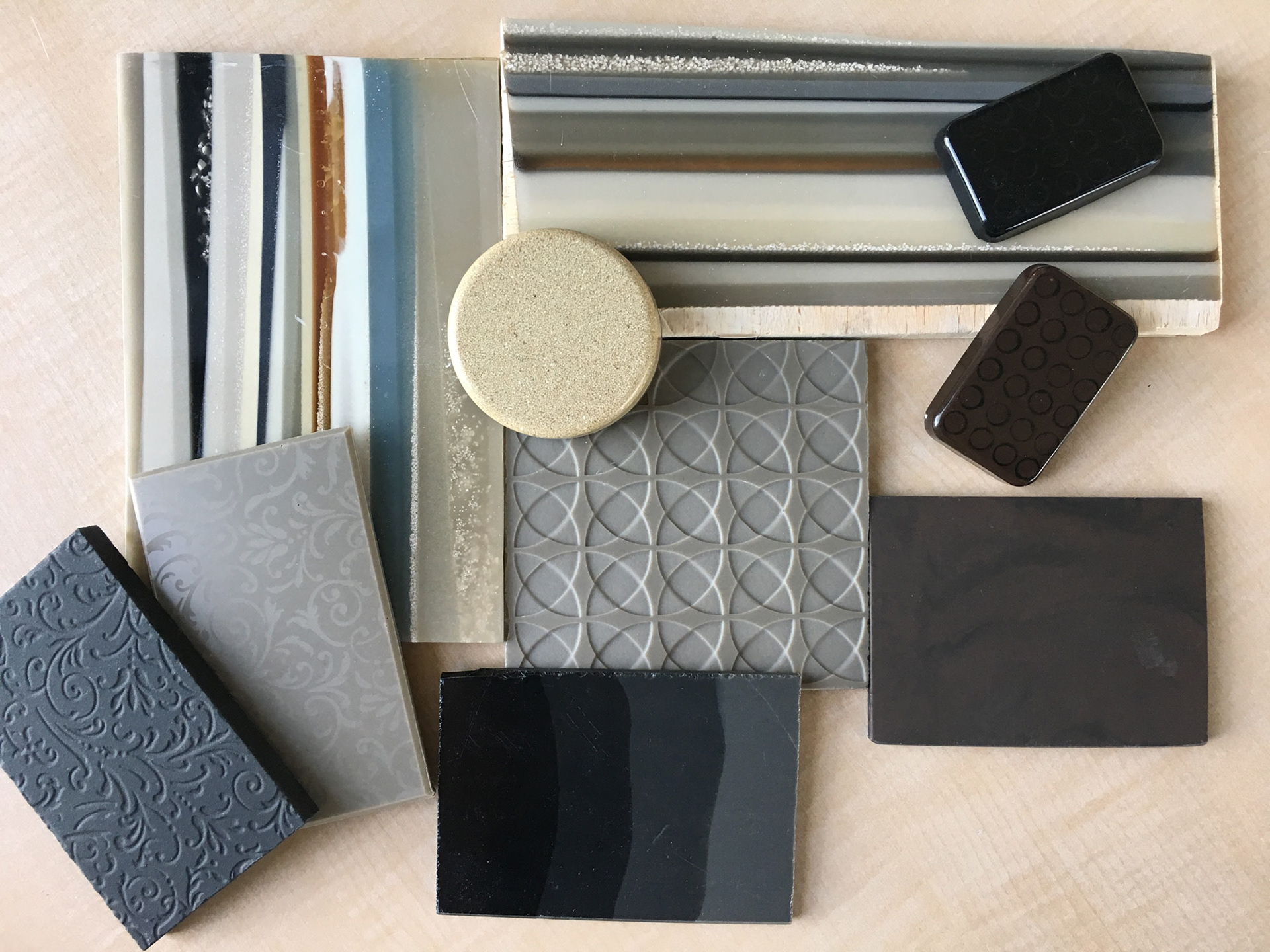

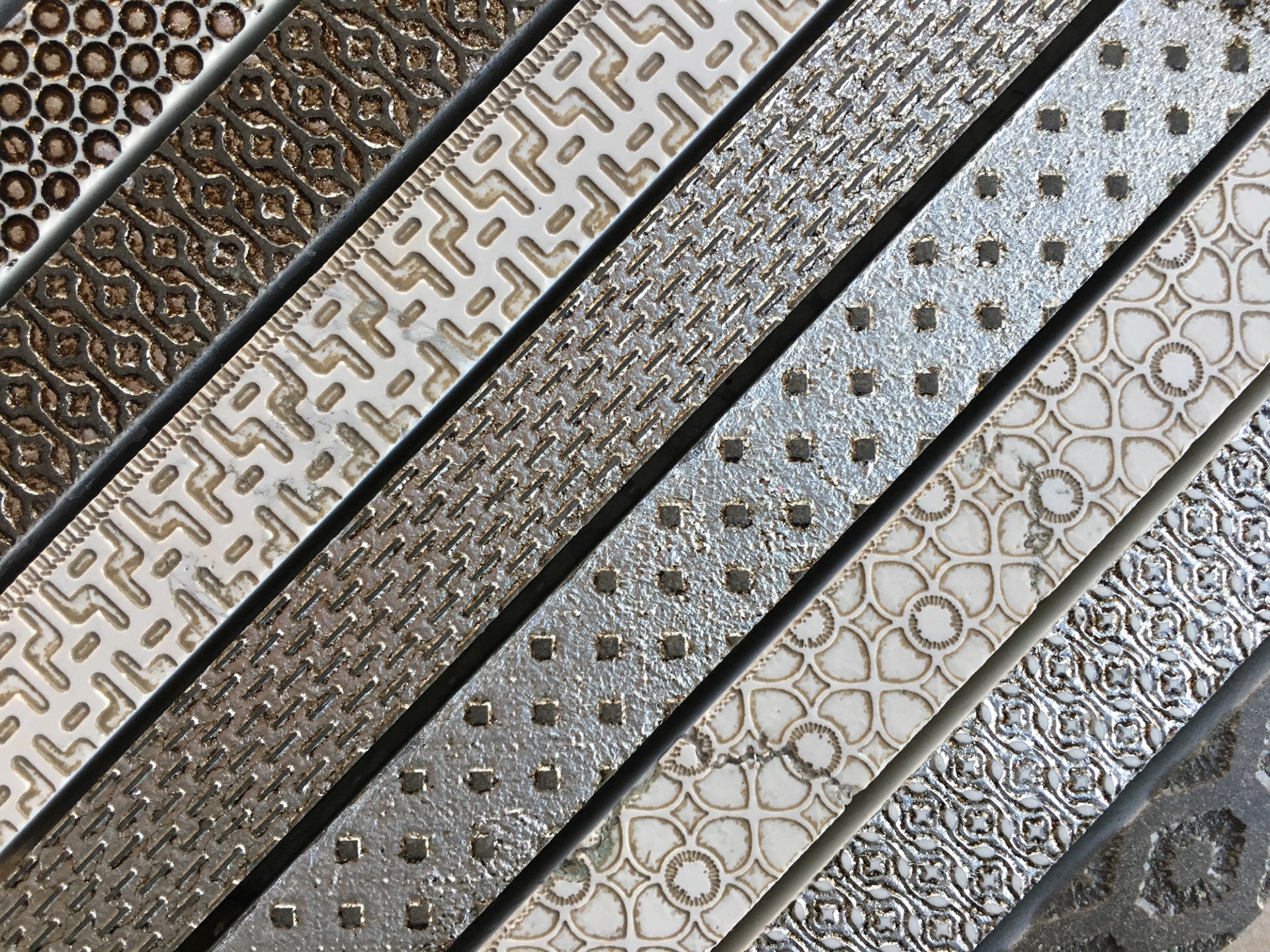

Advanced Materials are considered the lifeblood of Kohler Company. Material and process exploration was at the core of my role as design manager for color/material/finish. Innovations in both new and established processes was the expectation. I deepened my understanding of Kohler's core material sets and produced a pipeline of products featuring new process innovations, never industrialized before within the kitchen & bath industry. Highlighted techniques:

Ceramic/Vitreous: slip-casting, dry-pressing, CNC finishing, glaze masking, screen-printed decal transfers (micas, halftones, raised fluxes, precious metals, textural underlayers), glaze chemistry (translucent, opaque, honed, gloss, dimensional, and reactive effects), layering techniques (tinted body, engobes, and glazes).

Composites: dye sublimation, direct digital printing, dimensional digital printing, in-mold relief, in-mold texture, formulaic development (epoxy, ceramic, and sheet molding compound), waste stream recycling.

Glass: pressing, spinning, casting, slumping, back-painting, hot color inclusion, recycling, specialty finishing (iridescence and gold-foil).

Metals: casting, etching, PVD coating, enameling, in-mold relief, sandblasting, heat patinas, flame-spraying.

Stone: CNC forming, etching, gilding, water-jet cutting, sealing.

Company: Kohler Co. Date: 2010 - 2018. Involvement: CMF strategy, project scoping, creative direction, cross-functional problem solving, presentation for executive approval.